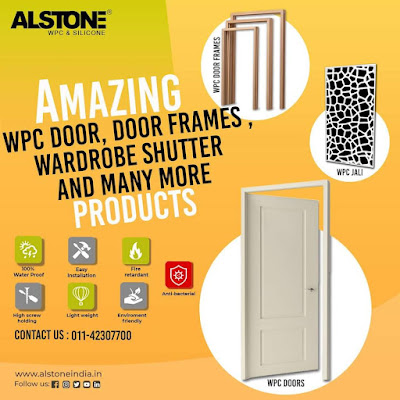

Why Architects Prefer Alstone WPC Door Frames for their projects

?

Architects always face a few questions that give them thought in

the back of their mind that “Will the choice of their product they would be

using will work for them or not!” And group housing builders who have to deal

with the product from scratch to end, often have few queries regarding the

product, when the product is timber door frames!

They mostly encounter lack of awareness and understanding,

unwillingness to shift from something that has been used since ages becomes a

daunting task.

Timber door frames are one of the most used conventional

products in the building material industry that has been there for decades.

But, this does not mean that it is a product of comfort for group housing

builders to work with!

But the fact that Timber being a natural product has its own

limitations which makes this material incompetant with the changing times and

trends of the building material industry.

Every project is special and has its own requirements which

timber fails to fulfill due to various Drawbacks like Swelling with water

retention, knotting, cracking, short life span etc.

Group Housing and vertical construction has become the new

normal with the changing construction demands. which poses a lot of challenges

with conventional timber.

We understand the hassles group housing builders have faced all

these years with Timber door frames in their workability, product wastage,

cost-effectiveness, and whatnot! As we know, Timber is natural

wood, its properties are solely natural which cannot be altered, this becomes a

huge drawback for a group housing builder to deal with.

We researched with over 300+ Architects and 500+ Group housing

builders and have compiled 8 Most frequently asked questions, just for you!

Q.1 Is there any timber substitute with the same strength and

performance?

Interacting and researching with Various Group Housing builders and

their Deliverable requirements in their projects, we concluded that WPC – Wood

polymer composite is swiftly emerging as the most successful substitute for

conventional Timber And becoming Architect‘s Favourite!

As it not only exceeds the strength and sturdiness but completely

eliminates the threats of failing under nature deemed conditions.

Q2. What is this product and what is it made of?

Wood Polymer Composite is a hybrid alternative material that has a

composition of herculean elements. It consists of 70% Virgin Polymers, 15% wood

powder, and 15% Harmful VOC/ Formaldehyde free Additives making this an

absolutely Ingenious.

Q3. Is it comparable in terms of costs?

When it comes to WPC, like timber all sorts of qualities from cheap to

premium are available in the markets and as quoted by Steve jobs – “Quality is

more important than quantity. One home run is much better than two doubles.”

And you can still optimise your costs by choosing the section sizes in

accordance to the wall thickness and size of your Door opening.For Example – A

75×45 / 90×45 section will work perfectly fine for toilets while a 100 x 50

/100 x 60 can be used for internal rooms. Thus instead of using a standard for

all internal applications, making an informed decision can save you those

hard-earned bucks!

Q4. Is WPC compatible for internal as well as external applications?

Absolutely yes! WPC Door Frames are internal as well as external

friendly. As discussed above performance largely depends on the quality of the

product. Alstone WPC Solutions is one of the few companies in the market which

swears by their premium quality products and services and delivers as

committed. Their technology which creates a rigid encapsulated

layer all around the frame gives it its high density and strengthened core,

making it a premium and reliable range!

Q5. What is the difference in ROI( Return on Investments) of WPC &

Timber Frames?

Then a natural product like timber frame is used, the initial cost may be

low, but in due course of time, it demands constant maintenance and renovation

whereas WPC Frames are Plug and Play which you can absolutely Fix and forget!

As it does not get affected by nature’s constraints like moisture, humidity,

termite/borer or any kind of microbe infestations. Being a polymer-based

product, it has increased durability and strength, thus a product for

generations, and High ROI in the long run!

Q6. How does the installation of WPC door frames take place and who is responsible for it?

The best part of WPC door frames is it can be worked upon with

Conventional woodworking tools and machinery, by your own trusted carpenter!As

it’s a Timber substitute the Working tools and techniques remain absolutely the

same and does not require a new rocket science to be learnt. It’s easy

workability and plug and play assembling adds exponentially to the list of

USPs.

You can refer to complete installation and assembling guide videos

on Alstone Youtube Channel to educate you

carpenters with added ease.

Q7. Will WPC door frames be as sturdy as wooden door frames or not?

Again, Absolutely yes! With Alstone WPC, you get premium quality WPC

Solutions that are high in density, durable, and have a longer life span.

Additionally, using WPC door frames for

your projects reduces dead weight load of your structure as they are light in

weight and require less manpower to handle and install.

Q 8. What construction type is it suited for?

WPC is emerging as the most successful substitute and taking the

industry by storm! Its features create a perfect balance of sustainability by

being a Green product, versatility as it can be used in every kind of project

where you can imagine timber and aesthetics as its an engineered, finished and

ready to use product!

For more information please visit www.alstoneindia.in

or call us at 011-42307700

Your blog very helpful. Thanks for sharing....

ReplyDeletetop wpc board manufacturers

imported wpc boards suppliers