Everything You Need to Know about WPC Boards & Plywood For Your Commercial Designs!: Since business trends are growing, businesses are looking for innovative designs that meet the demands of a vibrant workplace! When an architect decides to design the interior of commercial space, lots of options come to mind.

But, picking the correct material is the main issue that an architect faces. Plywood and WPC (also known as Wood polymer Composite) are the most frequently used and most commonly chosen from all the materials on the market.

Which one would you prefer? Both are highly regarded construction materials due to their strength, durability, and workability. They are available in different grades that can be used according to specifications, resources, or applications.

Composition and Manufacturing

Understanding the composition of the material is the best way to assess the longevity of any material!

Plywood is engineered made from thin slices of natural wood, referred to as the veneers'. These veneers are joined to each other in layers, one over each other, with the adjacent panels that have their wood grains bent together. These veneers are connected with glue and then compressed with high pressure using synthetic resins such as Urea Formaldehyde and Phenol formaldehyde. These are then pressed under high pressure and then heated.

To make to form plywood.

In contrast, WPC boards are constructed from ground sawdust, which is well mixed and heated with thermoplastic resins and additives that give it superior characteristics. Nowadays, polymer-based plastics have become frequently employed. The pattern of wood grains and wood powder is about 15% recycled, or virgin plastic is 75%, while the rest could be various additives.

Note: Alstone Industries uses additives such as stabilizers, fillers, UV pigments, and essential chemical agents to avoid harmful chemicals such as VOCs and Phenol-Formaldehyde, to give WPC boards a healthy, clean and hygienic environment!

Thus, the elements are mixed to form a dense consistency and then molded or extruded to create WPC boards.

Moisture Resistance and termite resistance qualities

WPC boards are a mixture of polymers and sawdust, and they are water/moisture-proof and termite-proof. This is because of its hybrid structure, thanks to which they are successfully used in applications such as wet patches, furniture, exteriors, bathroom interiors, etc., without any concerns!

However, plywood with grades that differ from Marine is not water and moisture resistant, but not waterproof as WPC boards!

Resistance to Heat and Fire? Resistant!

One of the main characteristics of a substance is its ability to resist fire during times of crisis! Since if a scenario comes on like this, the damages to the property and furniture result in a significant loss. And if you select an item like plywood, it is crucial to know that it is a flame-igniter and is more prone to heat.

In WPC boards, WPC boards don't cost huge damages since they stop fire because of their plastic and other special additives.

Plywood may have fire-resistant properties. However, WPC boards are much better than plywood.

Stability of Workability Dimensional Stability

From carpenter-friendly materials through engineered alternatives, WPC & Plywood both have many new features to explore in the changing construction material industry!

Plywood is indeed bendable without impacting its strength. However, planning and molding are not feasible like Wood or WPC because of its cross-layered structure.

WPC offers the combined properties of wood and thermoplastics. Therefore, it is much more flexible and adaptable than wood and can be made into any shape. They can also be designed, molded, and grooved just like wood. However, WPC is completely wood-working carpenter comfortable, as an engineered, pre-finished solution that is ready to use the product, making it a superior choice to plywood.

Plywood is not a viable material to use in its raw form, and plywood must be covered by laminate or veneers to mimic the colors or designs, which can increase the cost at the same time. Since the laminates and veneers are applied, they also have the potential for maintenance since they can peel off after repeated exposure to sunlight or water.

For WPC boards, The colors are developed by adding pigments as part of the manufacturing process and will not fade in sunlight. WPC doesn't require glue, veneer, paints, or polish since it is a shiny, bright material!

However, suppose you prefer to use laminates or veneers in your home. In that case, they can fix them by ensuring thorough roughening of their surface and then treatment using specific adhesives and double side adhesive tapes. They can also be painted using PU/Duco paint and texture paint following primer made of plastic.

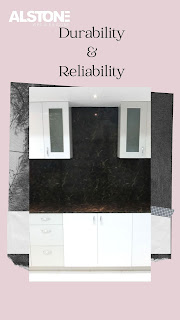

Durability & Reliability

WPC always has a lifetime guarantee from significant manufacturers, whereas the quality of the plywood is a factor that determines longevity and durability. Due to a variety of plywood makers, their grades could be affected. Ensure that your purchase material comes from a respected manufacturer with the proper tests certificates and approvals. If you decide to go with Alstone Industries offers each of the credentials to create sturdy designs using quality WPC.

Alstone industries WPC boards are extruded or molded into sheets. Unlike plywood, they are homogeneous, composed of layers glued together, and fail.

Eco-Friendliness

Creating sustainable and sustainable projects is becoming the top trend of the 21st century. To do eco-friendly projects, you need an environmentally-friendly material! Creating plywood causes the loss of forest land, which doesn't make it a sustainable option. Additionally, plywood veneers are created by cutting down trees and aren't environmentally friendly.

But, WPC is made from wood waste, wood powder, and recycled plastics, and it eats industrial wastes and transforms them into valuable materials. WPC manufacturing doesn't produce any waste, nor are trees removed during the process, and is an eco-friendly product.

Thus, WPC stands out as an alternative to plywood!

Connect with our experts +91 9810846953 to get queries clear about WPC board applications today or mail us at: info@reynobondindia.com

Nice post. Thanks for sharing..

ReplyDeletewood plastic composite manufacturers from Andhra Pradesh

wood plastic composite manufacturers from Karnataka